The Art of Wynwood Cigar Factory

Miami, FL – June 4, 2013 – Miami might have Little Havana, but it’s Wynwood Arts District that is making its way to be the next major cigar producer in the city. You might’ve seen the incredible new Evoca1 mural on the side of a building in Wynwood that looks to be an art warehouse, and it is in a way, but what you probably don’t know is that it’s home to the Wynwood Cigar Factory. Once you set foot on the property, you’ll notice the distinct aroma of tobacco wafting through the air, and if you wander inside, you’ll see everything being rolled up right before your eyes by native Hondurans. To add to an already captivating visual, these workers sit at bright, beautifully colored hand-painted desks, with three of the four walls in the huge space covered with artistic murals. It wouldn’t be Wynwood without the art, and this place takes cigar making to a whole new level, weaving in the work of local artists into their own artisanal creations.

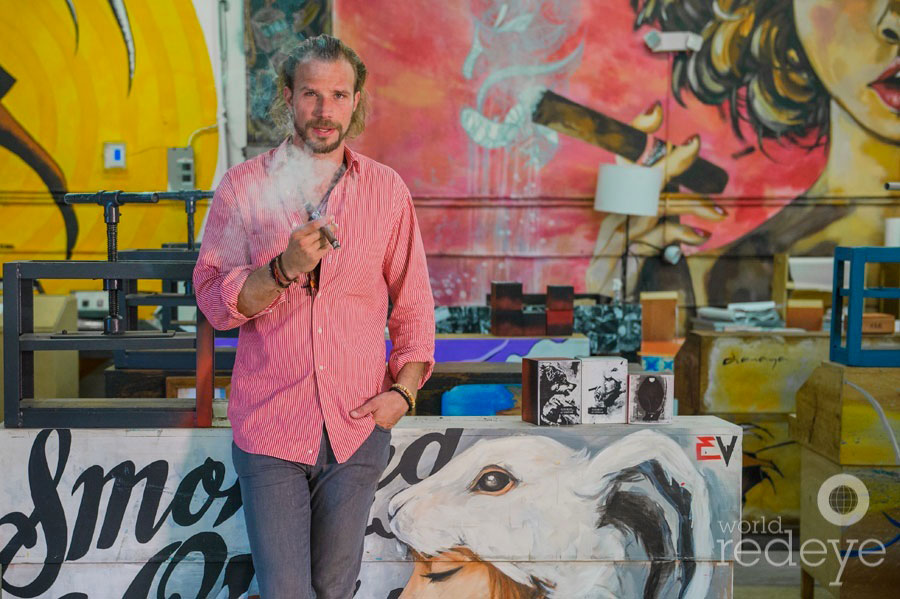

And who better to breathe life back into one of South Florida’s earliest industries than a Miami native? Robert Caldwell is the guy who brought this vision to reality with his partner Christian Eiroa. Just this past January they opened the factory for manufacturing, making it just barely six months old. Caldwell grew up in Coral Gables and has a great love for Miami, wanting to put it back on the map as a cigar producing city. He started smoking at the age of 12 and successfully started The Hotel Humidor company five years ago to service cigars to hotel groups. When Eiroa sold his big enterprise, Camacho Cigars, he wanted to team up with Caldwell because he had been the only one able to make hospitality cigars work.

Caldwell’s love for cigars and Miami come through in this project, which already has an extensive reach outside of Florida. Almost all of the cigars manufactured in Wynwood are shipped to retailers and hospitality groups elsewhere, with only some of the very exclusive product being sold here in Miami. There’s even a bigger factory in Honduras that sits on a 1,500 acre tobacco farm, which provides a lot of the leaves, and even the workers, found in Wynwood. The 5,000 square foot warehouse is a cigar factory, lounge, and art gallery all in one, making it a unique commodity that brings something new to the up-and-coming neighborhood. Take a tour of the space with Caldwell himself, and learn just how the Wynwood Cigar Factory sets itself apart from the rest by staying true to the art of cigar making while simultaneously showcasing local artists.

Robert Caldwell

“When you think about cigars, you think of all these countries- Cuba, Dominican Republic- you don’t think of a brand. The purpose is to give Miami a born-and-bred brand. Wynwood is the new Miami, so the new Miami brand needs to be from Wynwood. When most people think of Miami, they think of little hole in the wall factories- the whole manufacturing district of Little Havana is just bullsh*t.”

“This is the ‘Escaparate’ room. It’s a storage area for when the cigars are rolled and ready; they just sit here and relax anywhere from six to 24 hours before getting shipped.”

The Escaparate room has bags of scrap tobacco left over from manufacturing the high-end cigars. Usually people sell it, but it’s too good to just be sold like that. Caldwell tells us that they’ll probably end up using it to make a cheaper cigar later on, like a cigarillo.

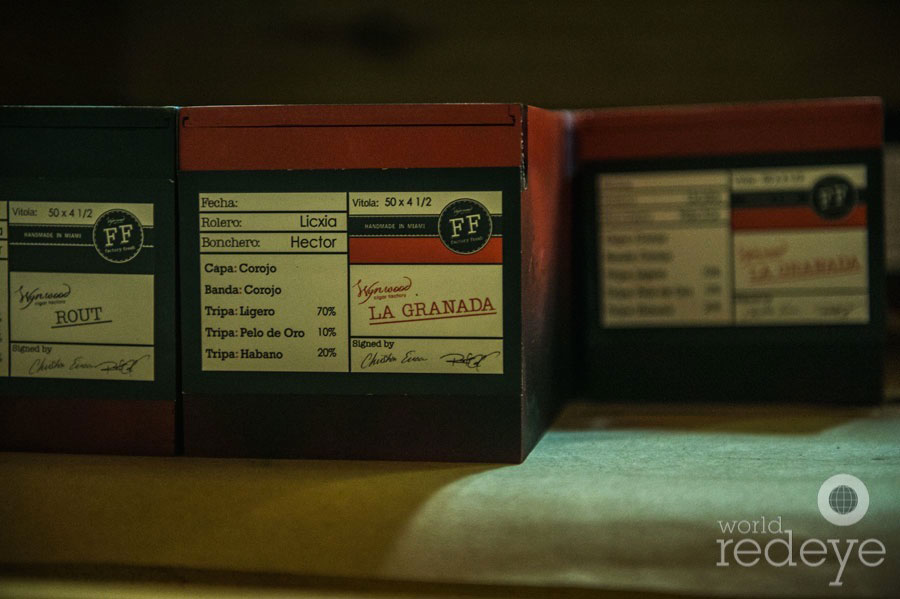

These boxes store and air out the three core tobaccos received from the factory in Honduras. Ligero is the strongest, with a pepper and spice flavor, that acts as mostly filler for the inside of the cigar. Pelo de Oro comes from Peru and adds more sweetness to the cigar. Habano is brought in from Nicaragua, adding a smooth, caramel, buttery component.

Robert Caldwell

“Each of the three main lines of cigars made in the factory blends a variety of these leaves. The farm which they’re sent from in Honduras has various micro-climates within the 1,500 acres. From one end of the farm to the other, the tastes can turn out completely different. Variations in priming, height of the leaf on the plant, and the age all make up a different blend of flavors.”

Caldwell and his partner had a vigorous hiring process for the exclusive factory. Since Miami isn’t exactly a destination city for hiring cigar manufacturing, they held a competition in Honduras with 5,000 rollers. To find the best of the best, they then narrowed it down to 300 rollers based on the cosmetics of the cigars. After that, the structure was the second criteria, narrowing it down to just 50. Then, these 50 were unidentifiably different to the eye and feel, so they rolled a second cigar. A machine was used to test the air resistance of the inside of the cigar, bringing it down to the final 20 rollers who had the perfect product. The first eight rollers are here on 15-month Cultural Exchange visas, with the second wave coming soon. They have to keep switching them out, a tedious process, but well worth it for the best cigars.

The first step in the rolling process is to create what’s called a bunch. It’s prepared with an assistant tool used in Central America that makes the cigar burn a lot better. Some purists argue that the entire process should be done completely by hand, but that also gives a greater number of returns and a lower quality cigar. This is the one tool that they’ve been able to integrate to assist them. He takes five of the whole leaves, puts them into the tobacco binder, and rolls them.

The binder leaf is very important: it’s the one used on the outside of the roll that holds it all together and gives most of the initial flavor.

Then he uses a mold to shape them all uniformly. The cigars all get put into the slots, he puts the top on it, and stacks them. He applies a certain amount of pressure, usually until it stops twisting easily, adds an extra spin to it, and will just let them rest in there. They’ll rotate them to the other side once, then remove them.

Robert Caldwell

After they’re released from the mold, the cap is made. The roller, in this case it was a woman, takes a cylindrical tool to cut out a circle shape from the leaf. All of the cigars here use what’s called a triple cap to seal the cigar. It’s a Cuban method. They use vegetable glycerin- a cellulose plant base that’s flavorless and colorless- to seal the cap. It’s a very intricate and delicate process.

Once the cap is made, she then has a little tool to cut the cigar. She calibrates it to the desired size, then cuts it.

You can see the three distinct lines of the cap, hence it’s called a triple cap. It’s a more detailed process than most cigars, which just use a single cap. You also never want to cut a cigar below the cap, just off the tip, or else you’ll lose all the flavor when smoking it.

While the labels are all printed by machine, they each get a handmade touch by having paint splattered on them. That way, no two are the same, and it gives an extra artistic feel to the finished product.

There’s thermometers in the factory to constantly gauge the humidity percentage in the room. If it goes below 65%, sprinklers come on to mist the room and create some dampness so the product doesn’t dry out. The humidity stays between 65 and 70%.

Once they’re rolled and ready, they sit in the Escaparate room for a few hours or overnight. The sorting trays distinguish which cigars were rolled and on what day.

They then go into their boxes. On the outside of every box there’s a label with all the information: who made the cigars, what’s in the blend, the brand name, the size, and what date they were packaged- which is the very last thing. Wynwood Cigar Factory’s three “crown jewels”, as Caldwell refers to them, are: Granada, Coneja, and Rout.

Robert Caldwell

“The Coneja 46 is my favorite. It’s a Corona Gorda. The perfect moment to smoke one is anytime you have time to smoke. It’s not something you do when you’re rushed. They’re meant for times of leisure. People smoke cigarettes because they’re addicted, but people smoke cigars to relax. It’s like having a glass of wine. You’re not going to just pour it and chug it, but if it’s a time where you can sit down, put your feet up, and really enjoy it, that’s when you smoke. For me, I like being in my car with music or here, but not when I’m running around.”

“I like my job because I like being able to innovate. I like when people tell me I can’t do something. When I decided to build this factory, everybody said it was cool, but they didn’t think people would get it. Even still, people are skeptical to what I’m doing here, and I like to prove them wrong. I like to do things my way, and every day is a battle, even with my partner, because we have to agree on everything. Everything we do has to be top-tier, from the humidification to the label that goes on the cigar, the wrapping, the box sticker… Sometimes it’s a struggle and takes more time and energy, but if we want to be different, we have to do it right.”

The main artist collaboration is with Evoca1, who has two murals outside on the factory walls. He created the original logo and boxes for the Wynwood Miami cigars, and just went with the team to do some murals in Ohio. The factory really puts an emphasis on local artists and their work not only by featuring them on the packaging, but also by putting the artist’s name and website as a way to promote them too. It’s very much a mutual relationship.

Raul Flores designed all the Wynwood Honduras boxes and even painted a table that sits in the factory and is worked off of daily.

All the artists are locals, keeping with the mentality that Miami is what’s being represented and promoted here. Danny Cordero, a Miami local who’s also known as “Love the Bear”, did a limited edition set of boxes for the Miami outpost.

The quirky doll pictures that hang in the factory come from local artist Marcello Ibanez. He did the series specially for Wynwood Cigar Factory, adding to the gallery of artwork there, and also has other doll art, murals, and more in Wynwood.

Nick Mattioli did the graffiti-like murals in the factory, adding a street art element to the place.

Female artist Dianaya is from Spain but lives in Miami. She painted this wall and one of the desks specially for the factory.