Q&A: A Greener Tomorrow Featuring Johan Andreassen, CEO of Atlantic Sapphire

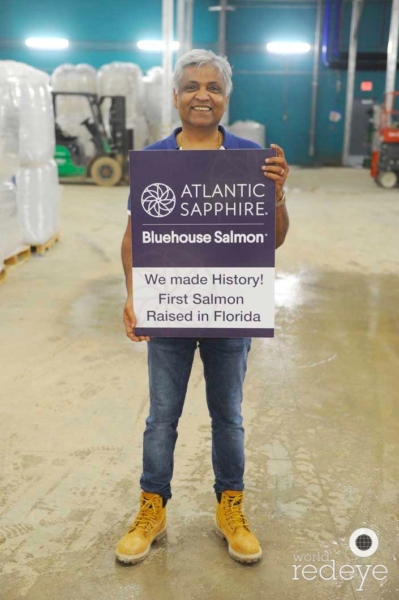

Johan Andreassen

Miami, FL – October 13, 2020 – Sustainability within industries has become increasingly relevant as consumers have shifted their focus towards the quality of their products, and companies towards their environmental footprint. People today value the process behind bringing their food from the farm (or sea) to the table, and salmon is no exception. Atlantic Sapphire, a company transforming the salmon industry with its proprietary Bluehouse™ facilities, has made a new home in South Florida with their first official Bluehouse™ on U.S. soil. The revolutionary bio-secure facility serves as the equivalent of a greenhouse, where fish are given ideal conditions to thrive with a 95 percent water-to-fish-ratio and a simulated environment allowing the salmon to swim against strong currents as they would in the wild. The first of its kind, the Miami Bluehouse specifically brings a new level of purity to the product with water sourced from the Floridian Aquifer — an ancient artesian aquifer that naturally purifies water through limestone rock.

This past month, the company celebrated a vision ten years in the making with its first U.S. harvest. With water sourced from the Floridian Aquifer, the Bluehouse Salmon is not only good for the consumer (delicious, heart-healthy, free of antibiotics, hormones, pesticides and microplastics), but also good for the environment. Innovative technology and aquaculture have yielded a land-based, sustainably raised, premium product in Florida that not only helps alleviate the pressure on wild fisheries, but also eliminates environmental concerns associated with conventional salmon farming. The first harvest serves as a pivotal moment in shaping the industry towards a greener tomorrow and gives us a glimpse into the possibilities for the future.

World Red Eye met up with Atlantic Sapphire’s chief executive officer, Johan Andreassen, to discuss the monumental first harvest and the journey towards a more sustainable future. Read the full Q&A below.

By Gaby Cuevas

Johan Andreassen

WRE: Tell us a little bit about Atlantic Sapphire. What kind of company is it? How did it come to be?

Johan Andreassen: Atlantic Sapphire is a company that is pioneering land-raised salmon farming with our proprietary Bluehouses. My partner (co-founder, Bjorn-Vegard Lovik) and I had the idea to help shape the salmon farming industry toward a more sustainable future. Initially we established Villa Organic, Norway’s first organic salmon farming company, with the revolutionary use of cleaner fish to fight sea lice in net pen salmon farming without the use of pharmaceuticals or chemicals. However, we knew there had to be a better alternative, and we partnered with co-founder Thue Holm, who had extensive experience in recirculating aquaculture systems (RAS) and worked to build a commercial pilot of a Bluehouse™ in an effort to eliminate farming with net pens in remote areas.

WRE: What sparked your interest in the salmon-farming industry?

JA: Salmon is the one of the most nutritious foods in the world, with high content in Omega 3 levels and minerals beneficial for brain and heart health. I am a salmon entrepreneur originally from Norway, the world’s largest salmon farming country and I have been involved in the sustainable development of the industry since the beginning of my career.

In the United States, more than 90% of the consumed salmon is imported. While U.S. salmon demand is the world’s largest in total volumes and is increasing year over year (not considering the exceptional impact of COVID-19), per capita consumption is still lower than many European nations. This gives us huge room for growth and the opportunity to reduce the existing deficit in production in the country. Consumers are showing increasing interest in healthy, sustainable protein, and raising salmon in a sustainable way is a key part of the solution.

Johan Andreassen

WRE: The company has revolutionized sustainable salmon-farming practices with the development of your proprietary Bluehouse™ facility. How did the idea for this concept come to be?

JA: With 90% of wild fisheries unable to sustain current demand, we took the concept of a greenhouse — which gives plants the ideal environment to thrive — and worked to reimagine fish farming by pioneering the Bluehouse™. The result is a bio-secure, simulated environment that allows our salmon to swim against strong currents, happy, healthy and stress free, as they would in the wild.

WRE: What are some of the benefits associated with salmon farming within a Bluehouse™?

JA: Simply put, the controlled environment results in an exquisite product. Our salmon are raised with no hormones, no antibiotics and no pesticides, all while putting no pressure on the wild fish populations. With the Bluehouse™, our fish swim in waters with the perfect current, temperature and salinity for the health and wellbeing at each stage of growth.

Johan Andreassen

We took the concept of a greenhouse — which gives plants the ideal environment to thrive — and worked to reimagine fish farming by pioneering the Bluehouse™.

Johan Andreassen

WRE: You chose Miami as the location for the first full-scale Bluehouse™ in the United States. What made you choose South Florida as opposed to other places?

JA: We wanted a location in the U.S. so that we could get our salmon to eaters across the nation at rapid speeds for freshness, at a fraction of the carbon footprint. The reasons for picking South Florida are three-fold. First, the state was a natural fit for aquaculture innovation because our water is sourced from the Floridian Aquifer — an ancient artesian aquifer that naturally purifies water through limestone rock — the location specifically yields a new level of purity to the product. Secondly, we’re able to partner with Florida farmers who can benefit from our up-cycled fish waste, and 99% of our water is recycled. Thirdly, Miami is the main U.S. hub in salmon trade; it has the necessary infrastructure and we have access to a local and international workforce (making this project a big contribution for employment in the area).

WRE: This month marks the company’s first US salmon harvest. Tell us about the process behind this. How long has this been in the making?

JA: From groundbreaking on the Miami facility to now, the process has taken about four years. However, this harvest is nearly ten years in the making if you consider the trials and modifications made with our pilot run in Denmark.

WRE: What does the future of sustainable salmon-farming look like? Are there plans to open up more Bluehouses across the United States?

JA: While there are no plans to open more Bluehouses in the United States, we are poised for exponential growth, which will only further contribute to a greener tomorrow. At current, our company is close to completion of its Phase 1 build out which is projected to harvest approximately 10,000 tons of salmon annually. Looking ahead, we’ve secured the key U.S. water permits to produce up to 90,000 tons onsite, and we have plans to increase our capacity to targeted harvest volumes of 220,000 tons by 2031.

Armin Ramirez & Johan Andreassen