Q&A: Breaking the Ice with Mixology Ice

Miami, FL – August 29, 2019 – Creating crystal clear ice is not just as simple as freezing water… Meet Carlos Leal and Fabian Alvarez the owners of Mixology Ice. Mixology Ice is the leading manufacturer, retailer, and distributor satisfying the growing demand of clear ice in the US. Leal and Alvarez, were running their mobile bar and cocktail service business Rum & Coffee Productions. Yes, their drinks were delicious, but the owners thought “what if the ice was bigger, better, and clearer?”. The two did their research to see what ice alternatives were available in the market, as a result in 2014 Mixology Ice was born.

Last year Mixology Ice sold a record number of clear ice, over half a million pieces through its operations in South Florida and NYC. From buying their first cases of ice from an ice sculpture, to becoming the largest manufacturing facility in the US, today they create on average 70-80k pieces per month. The company currently has nine employees in Miami and two in NYC with plans to open their newest location in Chicago this November, just in time for the holiday season. Mixology Ice is paving the way in the industry. We headed to their Miami facility to see exactly how it’s made. Read the full Q&A below as we broke the ice with Carlos Leal.

Carlos Leal & Fabian Alvarez

WRE: How did you get your start working in the industry?

Carlos Leal: We had our head start thanks to our mobile bars and the cocktail service we provided at the time while running Rum & Coffee Productions, our event production company. We stumbled upon the fact that ice wasn’t good enough for the growing demand of quality oriented cocktails that local and out of state legends were building in Miami. Better ice, bigger ice, and clearer ice was much needed and nowhere to be found.

WRE: You and your partner Fabian, created Mixology Ice in December 2014. Throughout the past 5 years, how has your business evolved?

CL: We have grown from a 1200 sq. ft facility into a 4500 sq. ft location, from buying our first cases of ice from an ice sculpture to become the largest manufacturing facility in the US with average of 70-80k pieces per month. The company currently has nine employees in Miami and two in NYC. We’re planning on opening our newest location in Chicago, this November just in time for Christmas. Mixology Ice has nearly 30% growth year to year, one retail patent and two more on the way. I’d say we are humbly contributing to generate knowledge for this industry, and most importantly we are helping expand the culture we all clear vendors are helping spread to regular walk-in clients.

WRE: How do you distribute the ice to your clients?

CL: We currently distribute seven days a week, 365 days a year to our clients wholesale or retail. We have two refrigerated vans for South Florida, one van in NYC and 126 foot truck for long hauls.

WRE: Currently, Mixology Ice sells directly B2B? What are your thoughts on selling directly B2C?

CL: We jumped into retail in early 2018, but we really scaled up in 2018-2019 with local presence in Mega Liquor stores, Pantry Liquor Stores and Vintage Liquor stores. We also bring our ice directly to costumers serving homes and office locations. We ship outside Florida, using Fedex overnight and thanks to that we serve brands and private clients anywhere in the country. The future is retail. Our goal is to make our ice available to everyone in a very innovative way. Expect surprises for 2020!

Carlos Leal

With no initial capital, we have build our own cash flow client to client. I guess at this point you can differentiate us as risk takers. We take risks when other would rather stay put. We invest constantly and without blinking…

Carlos Leal

WRE: Where is Mixology Ice made? How do you ensure the ice is free from minerals, bacteria, and sediments?

CL: Mixology Ice as a product is manufactured at 5065 NW 74th ave, suite 1, Miami. The process of making clear ice, Mixology Ice, goes first and foremost thru filtering the water using an industrial system using Charcoal filter, paper/membrane filter, Reverse Osmosis tube, UV light tube and Ozone box. These steps guarantee the water is clear from sediments, minerals and bacteria and microbes, in other words the water in purified so it would be the best raw material with no flavor, odor or anything that would get in the way of making the best ice.

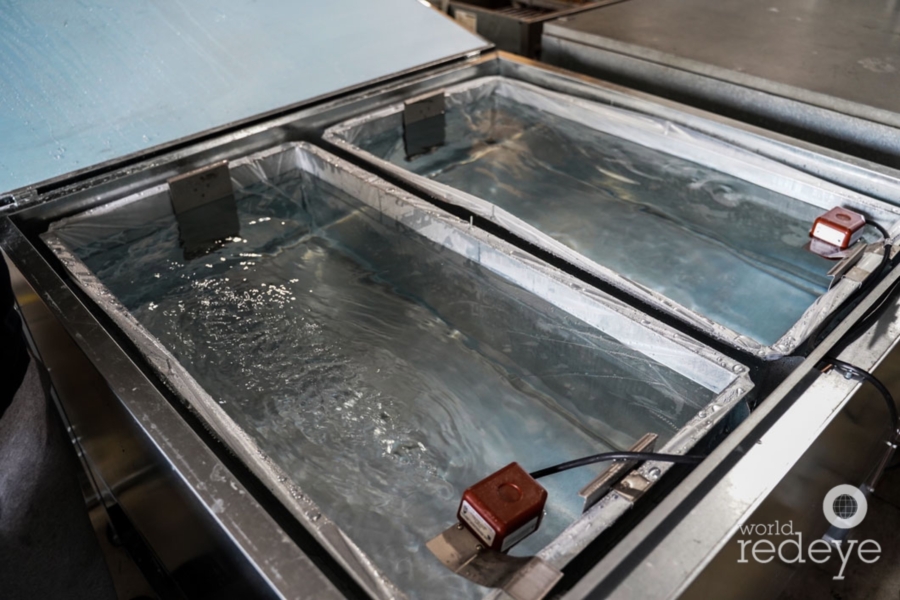

WRE: What is the next step in the production process?

CL: Water is frozen in dual tanks called Clinebells, prepared with directional freezing (from the bottom to the top) thus helping the ice to be formed only in that direction. The water is in movement thanks to two pumps ( one per block) that continuously circulate the water in order to expels the gases out. That is the secret of making clear ice: move the water while freezing. After five days, two blocks of 300 pounds of clear ice are born and harvest.

Carlos Leal

Carlos Leal

Carlos Leal

Carlos Leal

Carlos Leal

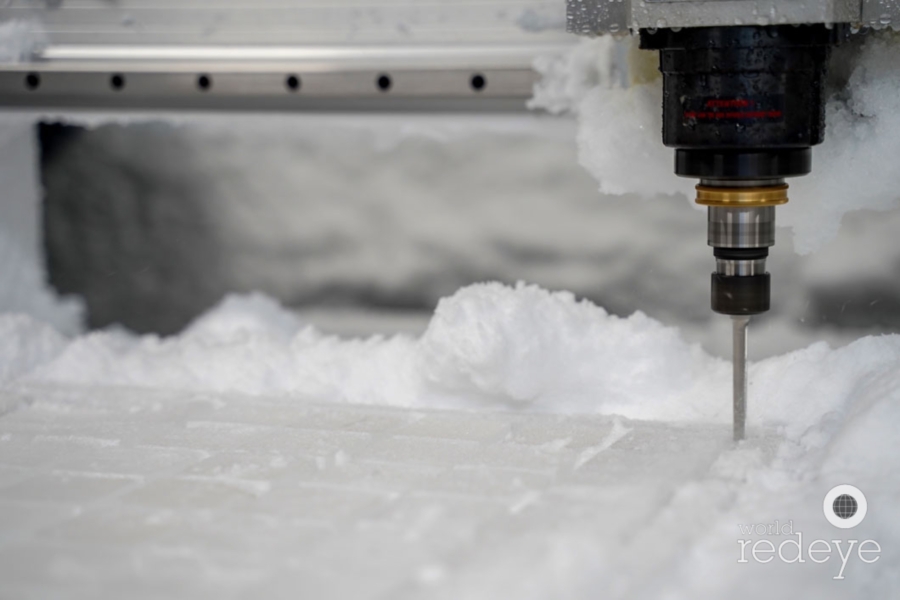

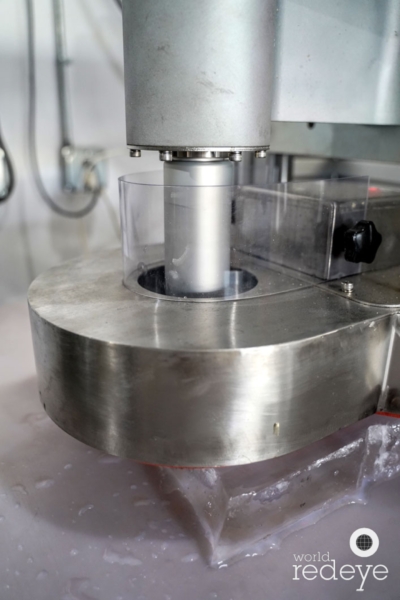

WRE: Mixology ice doesn’t look like your traditional piece of ice. How is the ice cut into perfect pieces?

CL: Blocks are stored in a freezer for one day for maturity and later cut using several machinery and human labor into custom pieces depending on the size of the glassware the client has. The artisan work is always present since we tailor almost 70% of the production to better serve the client needs.

WRE: Mixology Ice is the first clear ice company with a retail package patent and 2 more patents in the works. Tell us more about this accomplishment?

CL: The eagerness of reaching increasing levels of sales, the drive for new goals took us first to create a “tray” system that would hold the ice without sticking to each other. After 1 year of trial and error, we manage to achieve the perfect plastic blend that would help retain temperature while controlling humidity exchange from the inside to the outside of the cavities where the ice is. The tray is also flexible so you can easily push out the ice pieces one by one from the bottom without cracking the tray. Obviously, the first patent made easier to transport the ice, store the ice and bring it out of state with almost 0% breakage rate. In order to get the ice we needed to build machines, custom automatic machines that would help double-triple the capacity of production reducing human labor cost. This challenge led to our second patent: An invention that would trim and cut a full block of ice into the well known industry standard 2×2″ cube. That ultimately how we can attend more states and produce ice faster, and more efficiently. Last but no least the 3rd patent in the works, is an ordering system that would get ice closer to clients on a daily basis. 2020 will be the year we will deploy this technology first in Miami and then thru out the US, helping serve home needs for good ice more efficiently.

WRE: What differentiates Mixology Ice from other manufacturers?

CL: I think we are maybe the only ones with a great disadvantage, we are immigrants with no credit lines, with no personal assets or collateral. SBA programs aren’t truly mean to help, and they haven’t, not to day traditional banks, like Chase with whom with have been working for years now without a single personal or corporate credit cards. So we have build Mixology Ice out friends and family, shark loans and an incredible thrive from the team and the owners, facing really difficult times. With no initial capital, we have build our own cash flow client to client. I guess at this point you can differentiate us as risk takers. We take risks when other would rather stay put. We invest constantly and without blinking, even in low season, and we definitely have a very industrial approach. Its been overall a beautiful journey and you may say is actually taking shape now.

WRE: Mixology Ice is present in Florida, NY, and soon to open in Chicago. Do you have plans on further expansion?

CL: There is a big collaboration in the works, with a new centralized model in Tennessee that would help source our products within 1-2 days ground shipping, the same system Amazon would use. So, this is only the beginning.

Carlos Leal & Fabian Alvarez

Mixology Ice is humbly contributing to generate knowledge for this industry, and most importantly we are helping expand the culture we all clear vendors are helping spread to regular walk-in clients.

Carlos Leal